Heat resistance

■ Heat resistance level

|

|

A

|

B

|

C

|

D

|

|

Conductor temperature

|

HD, IEC

Rated temperature

|

90℃

|

90℃

|

70℃

|

70℃

|

|

HD, IEC

Test requirement

|

135℃×336h

|

80℃×168h

|

|

Insulation temperature

|

UL, CSA

Rated temperature

|

105℃

|

80℃

|

80℃

|

60℃

|

|

UL, CSA

Test requirement

|

136℃×168h

|

113℃×168h

|

100℃×168h

|

IEC : International Electrotechnical Commission

HD :Harmonized Document

UL : Underwriters Laboratories

CSA : Canadian Standard Association

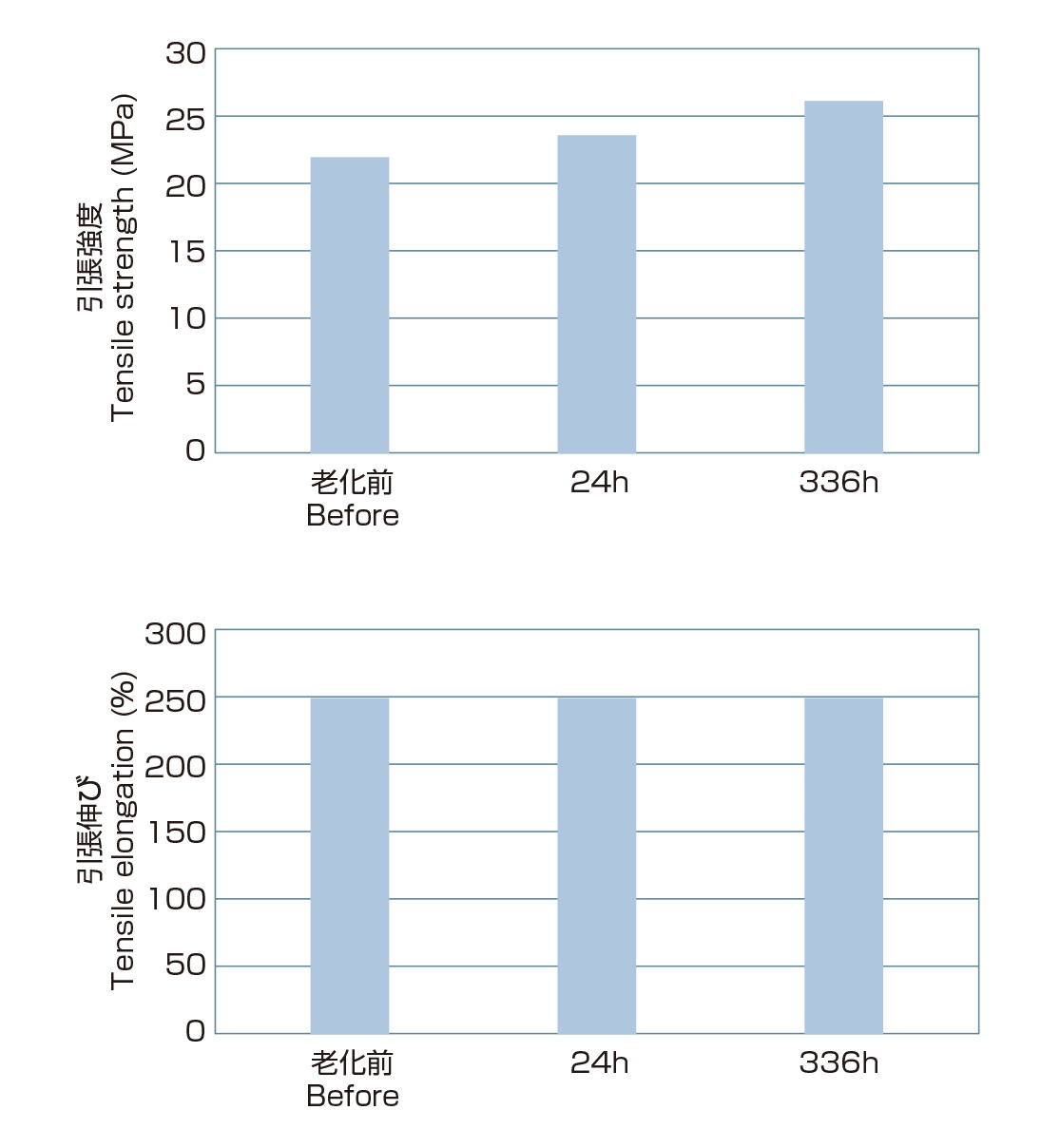

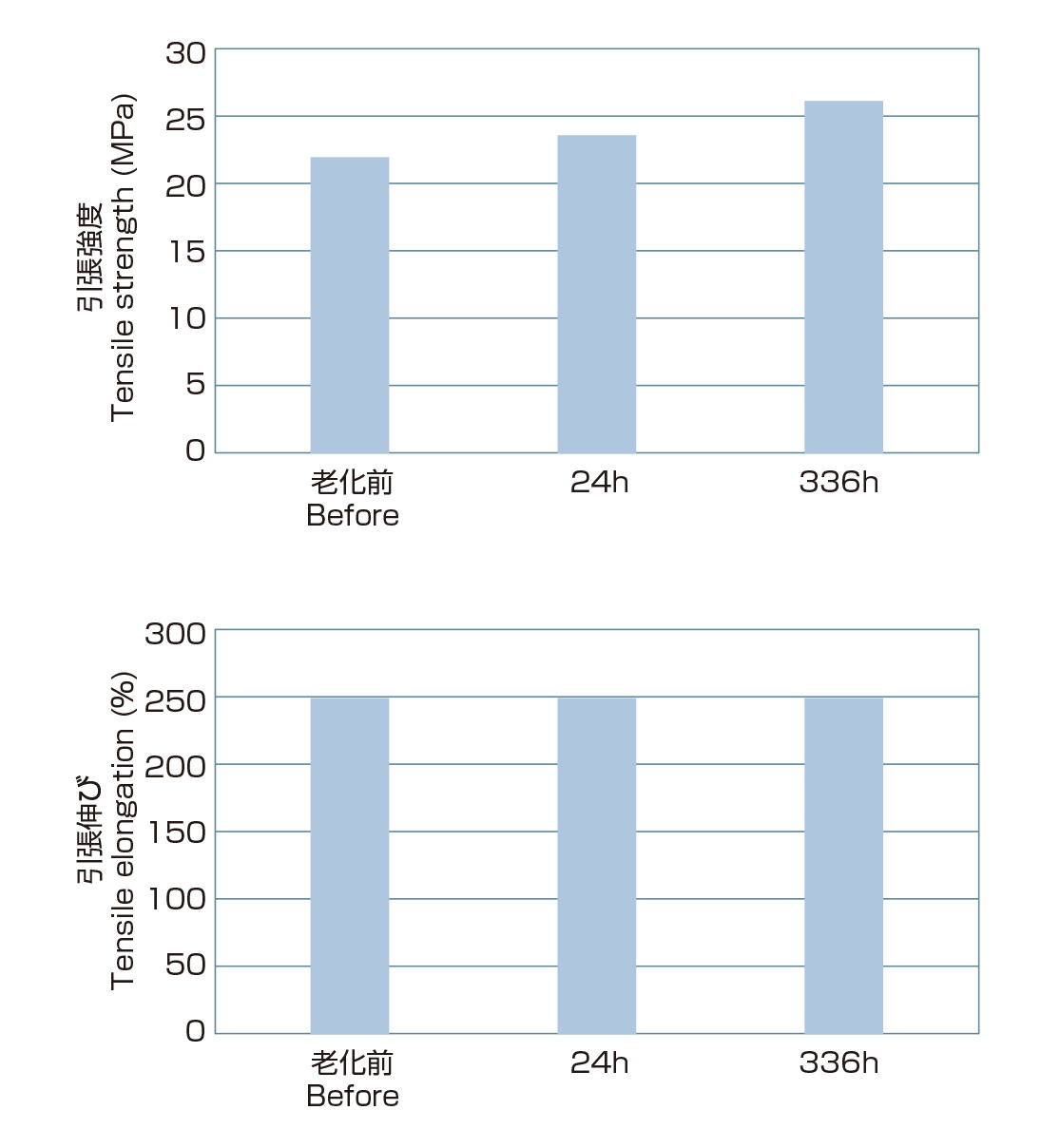

■ aging test Test result (135℃×336h) ex. RO-FLEX 170T(S)

※ This data is measurements and the reference.

Oil resistance

■ Oil resistance level

|

|

A

|

B

|

C

|

D

|

|

HD, IEC

|

90℃×168h

|

-

|

90℃×24h

|

-

|

|

UL, CSA

|

-

|

100℃× 96h

60℃×168h

|

-

|

-

|

|

JIS

|

-

|

-

|

-

|

70℃×4h

|

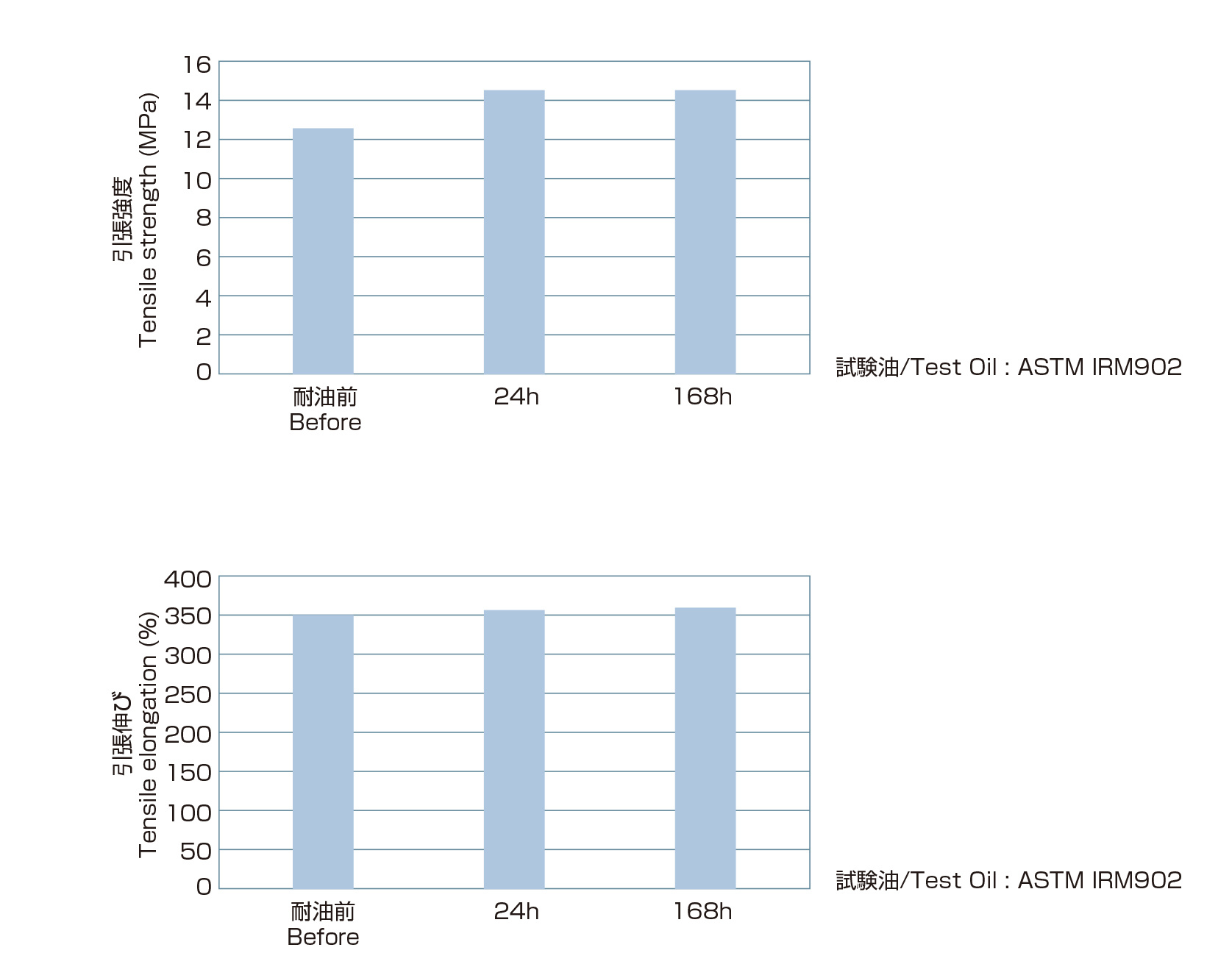

Test Oil : ASTM IRM902

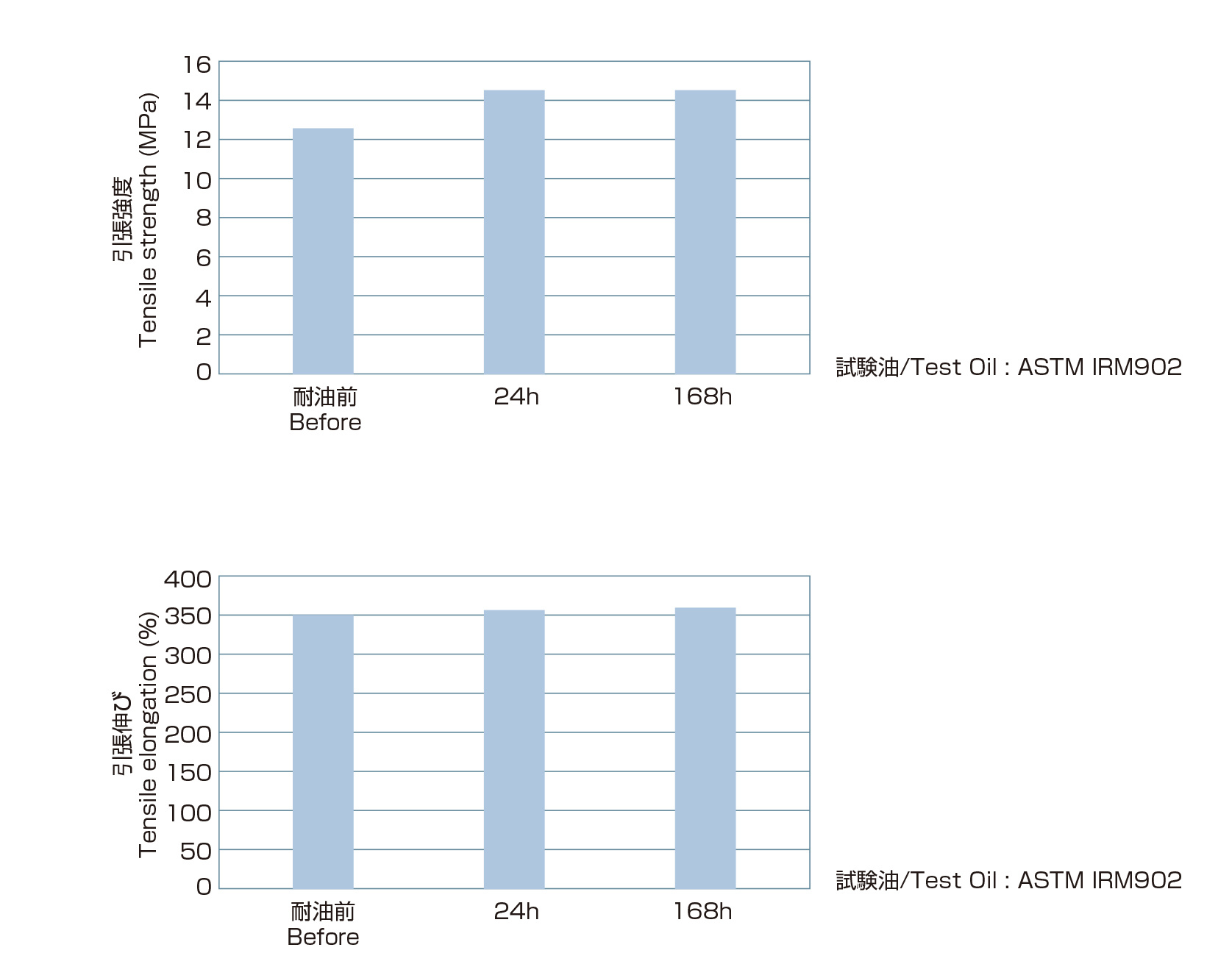

■ Oil resistance test Test result (90℃×24h, 168h) ex. RO-FLEX 340T(S)

Noise resistance

■ Noise resistance level

|

Contents

|

A

|

B

|

C

|

D

|

|

Braid shield

|

○

|

○

|

-

|

-

|

|

Twisted pair

|

○

|

-

|

○

|

-

|

【About noise】

Factors that cause noise include "electrostatic induction" and "electromagnetic induction."

【About "electrostatic induction"】

Electrostatic shielding prevents electrostatic induction. (There are copper shields, etc.)

Copper shielding is inexpensive, easy to process, and highly versatile.

However, it is effective only against electrostatic induction and not against electromagnetic induction.

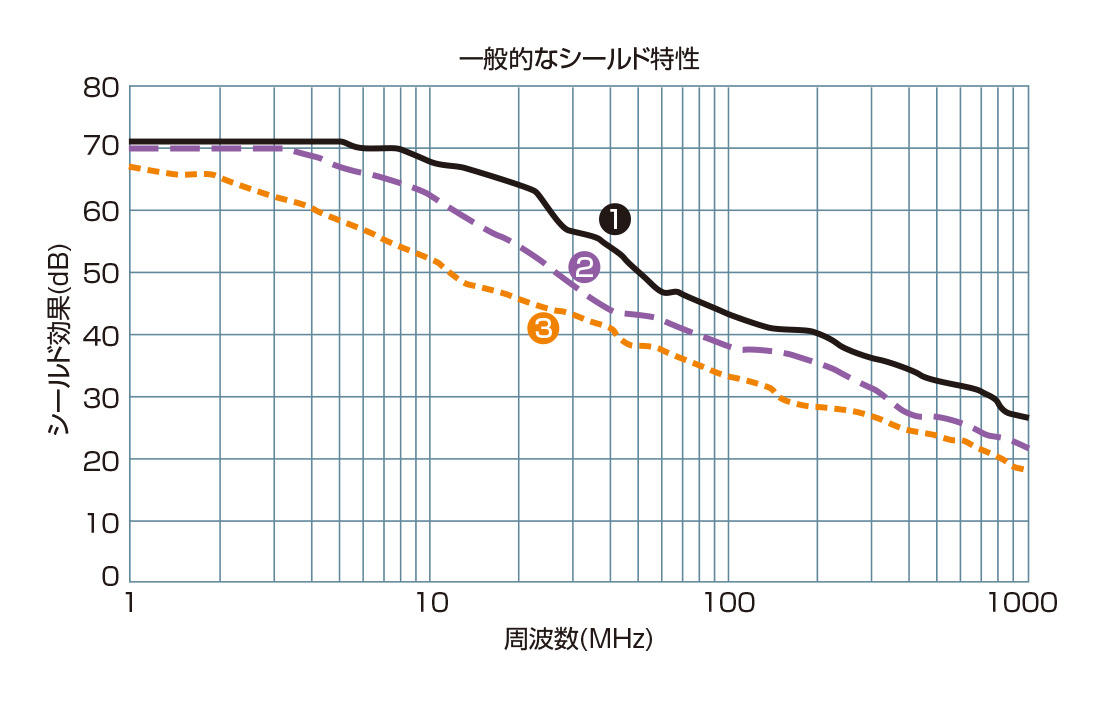

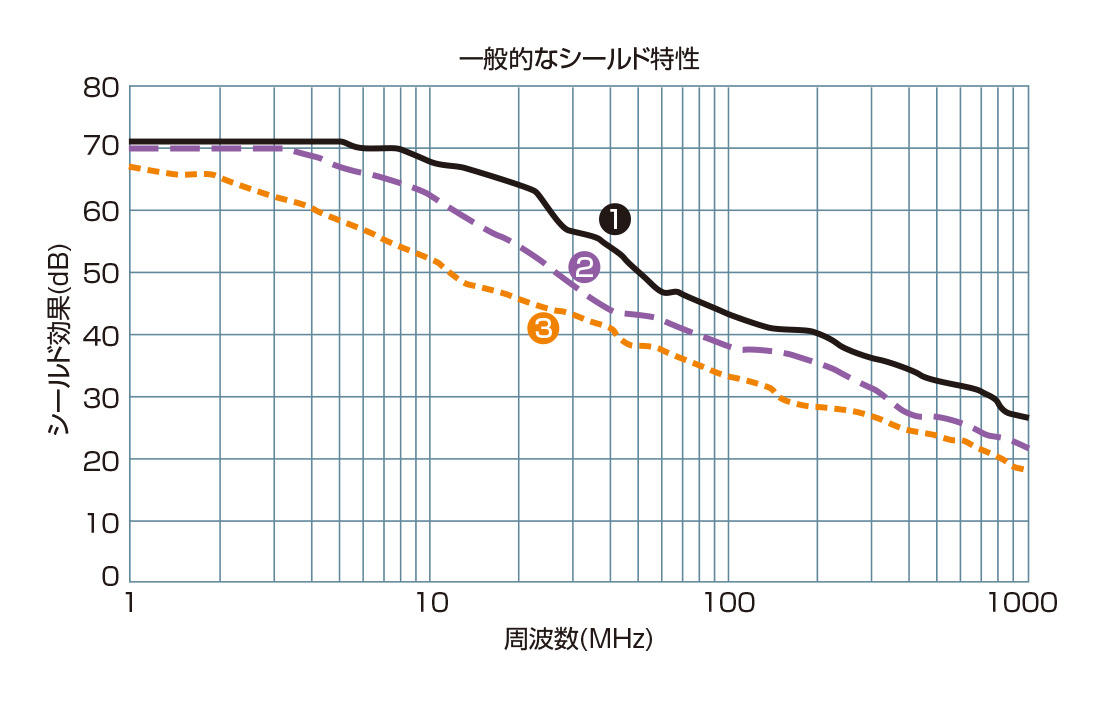

Type of shield

① Braided shield: Ideal for suppressing low frequency noise

② Spiral shield (horizontal shield): Good flexibility, bendability

③ Aluminum Polyester Shield: Lightweight and 100% density

【About "electromagnetic induction"】

A magnetic shield blocks electromagnetic induction.

Twisted wires are usually used to prevent noise caused by electromagnetic induction.

As a result, even if electromagnetic induction occurs, each wire cancels out the effect, making it possible to reduce noise by approximately 80 to 90%.

【Regarding EMC measures】

EMC(Electoro-Magnetic Compatibility)This is called electromagnetic compatibility or electromagnetic environment compatibility, and specifies the electromagnetic noise compatibility and immunity of electrical equipment.

EMI(Electoro Magnetic Interference):EMS (Electro Magnetic Interference Specification): Regulations regarding the influence of electronic equipment on itself: Regulations that set limits on the generation of noise that can affect other equipment.These regulations are collectively called EMC.

These regulations generally apply to all electronic equipment, including cables. This is because even if the same cable is used, the overall shielding effect will change depending on factors such as the combination of electronic devices and operating frequency. HD21.13 Transfer Impedance (surface transfer impedance) is specified as a requirement for cable shielding characteristics, and our shielded cables comply with the surface transfer impedance requirement of "250mΩ/m or less: 30MHz". Therefore, it is effective for EMC measures according to the EMC Directive (89/336/EEC).

Flame retardant

■ Flame reatrdant level

|

Standard

|

A

|

B

|

C

|

D

|

|

IEC

|

IEC60332-3

Category A

|

IEC60332-3

Category C

|

EN50265-2-1 (IEC60332-1)

|

IEC60332-2

Horizontal flame test

|

|

UL

|

-

|

VW-1 for CT use

|

VW-1

|

Horizontal flame test

|

|

CSA

|

-

|

FT4

|

FT1

|

FT2

|

|

JIS, JCS, PSE

|

-

|

JIS C 3521

JCS 7397

|

PSE flame retardant test

|

JIS C 3005

|

Caution : The products of Flame retardant level is an ability value.

|

Level A

|

Test outline

|

Apparatus

|

|

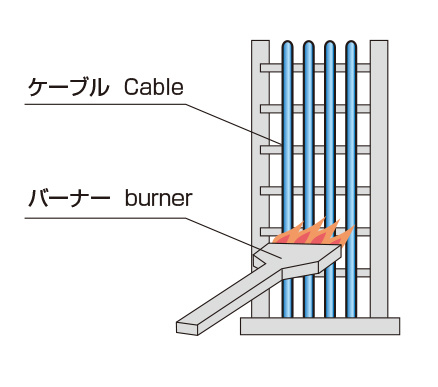

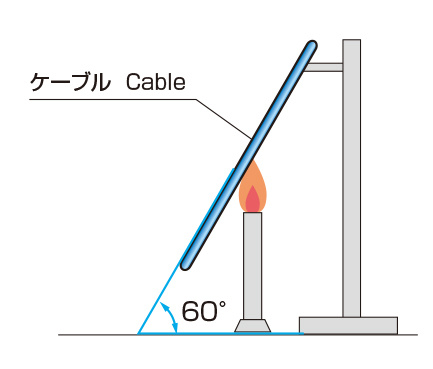

IEC60332-3

Category A

|

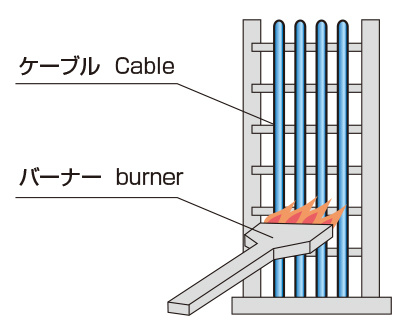

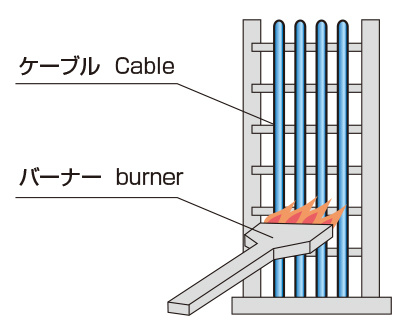

Cables of object : Vertically-mounted bunched wires or cables.

Sample : 3.5m

Nonmetal sample volume : 7L/m

Quantity of combustion : 70,000BTU/h(75,999kJ/h)

Flame application time : 40min

The wind velocity in the chamber : 0.386±0.038m/s

Judgement standard : ①The length of the cable damage from the bottom edge of the burner = under 2.5m

|

|

|

Level B

|

Test outline

|

Apparatus

|

|

VW-1 for CT use

|

Sample : 2.4m×number(Depend on the cable diameter)

Gas : LP Gas

Gas rule : 93MJ

Quantity of combustion : 70,000BTU(20kW)

Burner : Horizontal setting

Flame application time : 20min

Judgement standard :

①The length of the cable damage from the bottom edge of the cable tray = under 2.2m

|

|

|

CSA FT4

|

Sample : 2.3m×number(Depend on the cable diameter)

Gas : LP Gas

Gas rule : 85MJ

Quantity of combustion : 70,000BTU(20kW)

Burner : Slant 20°

Flame application time : 20min

Judgement standard : ①The length of the cable damage from the bottom edge of the burner = under 1.5m

|

|

IEC 60332-3 Category C

|

Cables of object : Vertically-mounted bunched wires or cables.

Sample : 3.5 m

Nonmetal sample volume : 1.5L/m

Quantity of combustion : 70,000BTU/h(75,999kJ/h))

Flame application time : 20min

The wind velocity in the chamber : 0.386±0.038m/s

Judgement standard :

①The length of the cable damage from the bottom edge of the burner = under 2.5m

|

|

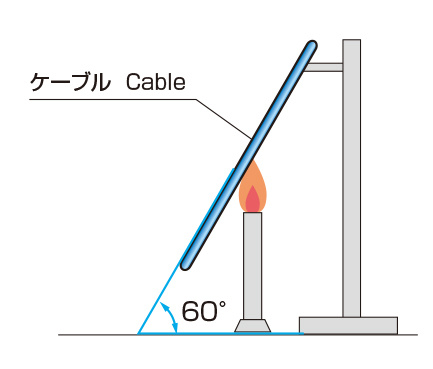

JIS C3521

JCS 7397

|

Flame test method for flame retardant sheath of communication cables.

Sample : 2.4m

Gas : LP Gas (JIS K2240 2-1)

Flame application time : 20min

Evaluation :

①After combusting a cable 20 min,the test is finished when the combustion of the cable stopped naturally.

②The damage length is measured, a burner is the starting point. The burner's height is 600mm from the tray bottom.

|

|

Level C

|

Test outline

|

Apparatus

|

|

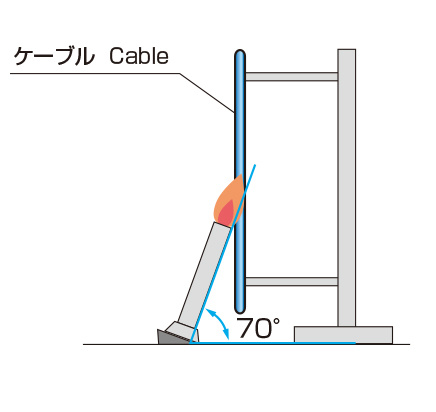

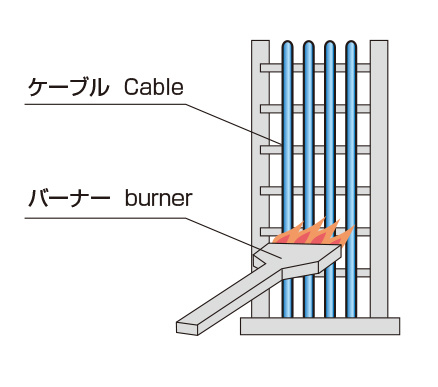

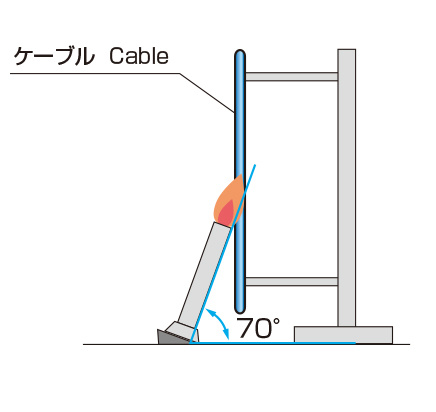

VW- 1

|

Sample : 610mm×1

Flame application time : 15 sec combustion and 15 sec stop → 5 times

Judgement standard :

①In all flame test, combustion time is not over 60 sec.

②The damage does not exceed 25% during the flame test or after removing the flame.

③Cotton do not catch fire by the flame or flaming.

|

|

|

FT1

|

Sample : 610mm×1

Burner: Chiril burner

Flame application time : 15 sec combustion and 15 sec stop → 5 times

Judgement standard :

①After five flame tests, combustion time is not over 60 sec.

②The indicator flag's damage does not exceed 25% after removing the flame.

|

|

EN50265-2-1 (IEC60332-1)

|

Sample : 600mm×1

Burner: 1kW gas burner, compliant with IEC60695-2-4/1.

Burner : Conform to the IEC 60695-2-4/1, gas burner of 1kW

Judgement standard :

①The length of cable damage = more than 50mm

②The length of downward limit of cable damage = less than 540mm

|

|

|

Level D

|

Test outline

|

Apparatus

|

|

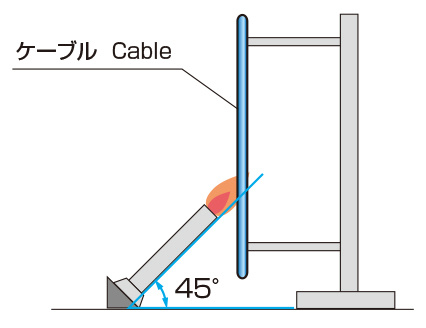

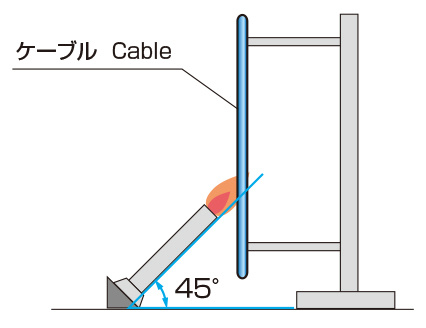

JIS C 3005

|

Test methods for rubber or plastic insulated wires and cables.

Sample : 300mm×1

Gas : About 37MJ/m3(900kcal/m3),Methane(Factory use)

Evaluation :

①Horizontal flame test : The bottom of the central part of the sample is exposed to flame till combustion,less than 30 sec.Examine degree of the damage after removing the flame.

②Slant flame test : After 20mm parts from the bottom edge of the sample is exposed to flame till combustion,less than 30 sec.Examine degree of the damage after removing the flame.

|

|

IEC : International Electrotechnical Commission

UL : Underwriters Laboratories

JIS : Japan Industrial Standard

CSA : Canadian Standard Association

JCS : Japanese Cable Makers' Association Standard

PSE : Denan Law

Flexing

■ Flexing level

|

Condition

|

A

|

B

|

C

|

D

|

|

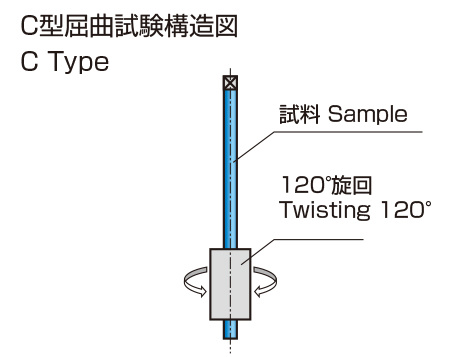

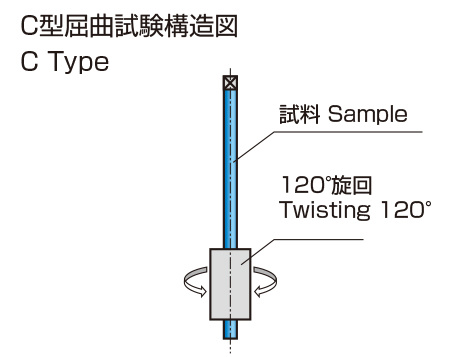

C Type

|

≧10,000,000 times/cycle

|

≧5,000,000 times/cycle

|

≧3,000,000 times/cycle

|

<3,000,000 times/cycle

|

|

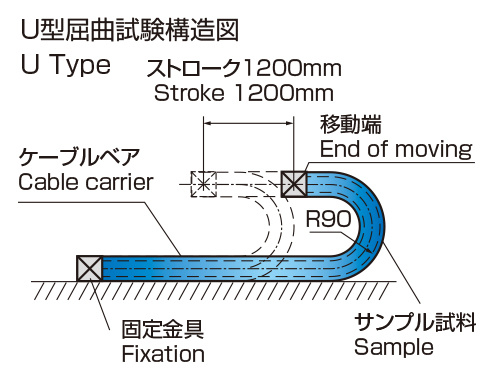

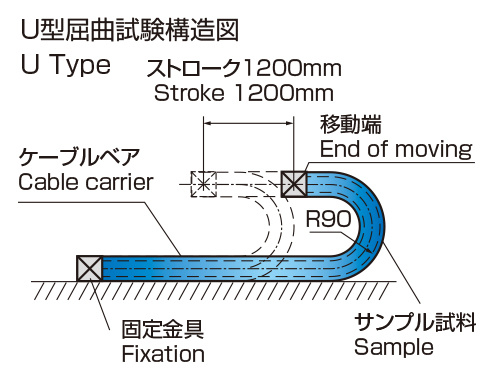

U Type

|

≧10,000,000 times/cycle

|

≧3,000,000 times/cycle

|

≧1,000,000 times/cycle

|

<1,000,000 times/cycle

|

|

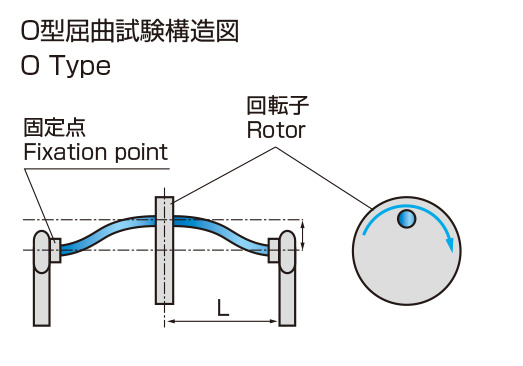

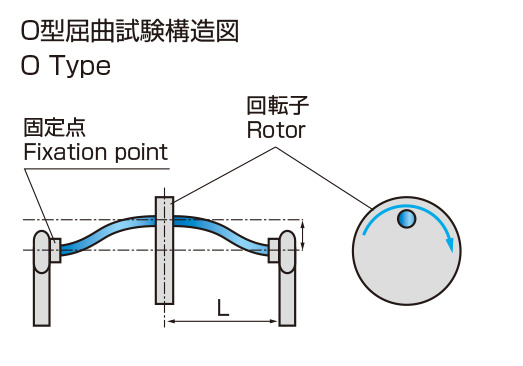

O Type

|

≧5,000,000 times/cycle

|

≧3,000,000 times/cycle

|

≧1,000,000 times/cycle

|

<1,000,000 times/cycle

|

|

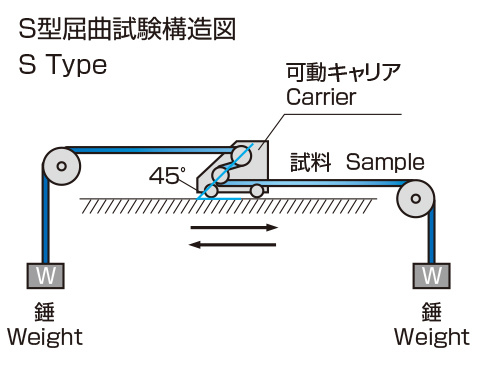

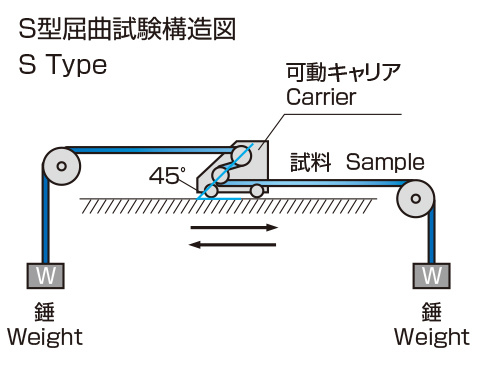

S Type

|

≧5,000,000 times/cycle

|

≧1,000,000 times/cycle

|

≧500,000 times/cycle

|

<500,000 times/cycle

|

|

Type

|

Test outline

|

Apparatus

|

|

C Type

|

Twisting at speed of 60times/min. Twisting each reversal 60゚.The outer damage and the conductor disconnection are inspected.

|

|

|

U Type

|

Bending at speed of 15times/min.Stroke is 1200mm.The outer damage and the conductor disconnection are inspected.

|

|

|

O Type

|

The test method is based of JIS C 3005.Turning the rotor at speed of 20times/min.The outer damage and the conductor disconnection are inspected.

|

|

|

S Type

|

The test method is based on Flexing test of HD21.2. The carrier makes cycle 1m.Moving at speed of 0.33m/s.The outer damage and the conductor disconnection are inspected.

|

|

|

Condition

|

A

|

B

|

C

|

D

|

|

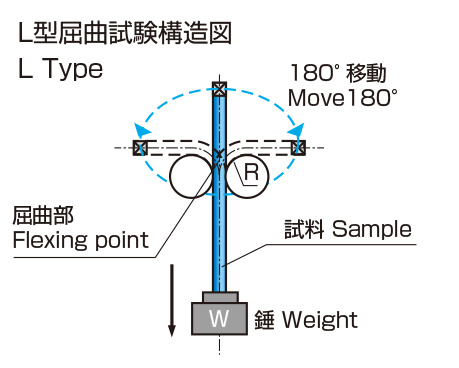

L Type

|

≧2,000,000 times/cycle

|

≧500,000 times/cycle

|

≧300,000 times/cycle

|

<300,000 times/cycle

|

|

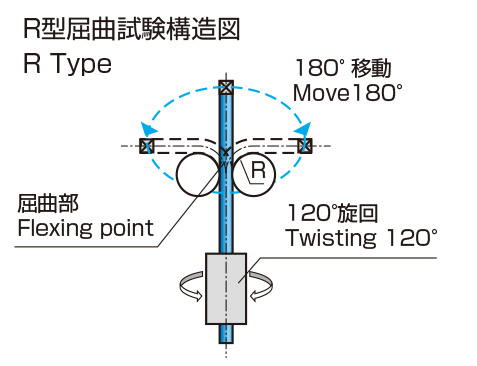

R Type

|

≧1,000,000 times/cycle

|

≧300,000 times/cycle

|

≧100,000 times/cycle

|

<100,000 times/cycle

|

|

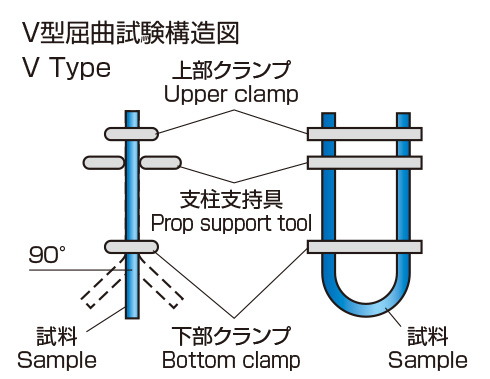

V Type

|

≧300,000 times/cycle

|

≧100,000 times/cycle

|

≧20,000 times/cycle

|

<20,000 times/cycle

|

※This data is reference value.

|

Type

|

Test outline

|

Apparatus

|

|

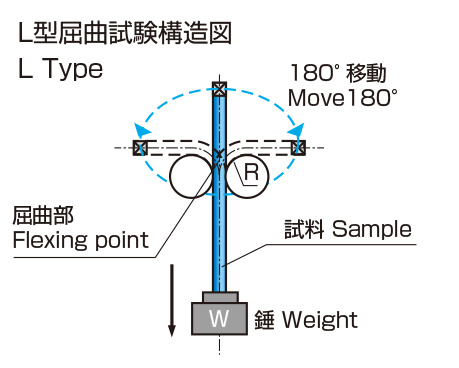

L Type

|

The test method is based on MIL-C-13777.

Bending at speed of 60times/min.The outer damage and the conductor disconnection are inspected.

R = 6D(D=Cable diameter)

W = 150g/mm²[>1.5mm² (Conductor cross-sectional area/Conductor sectional area)]

W = 500g/mm²[<1.0mm² (Conductor cross-sectional area/Conductor sectional area)]

|

|

|

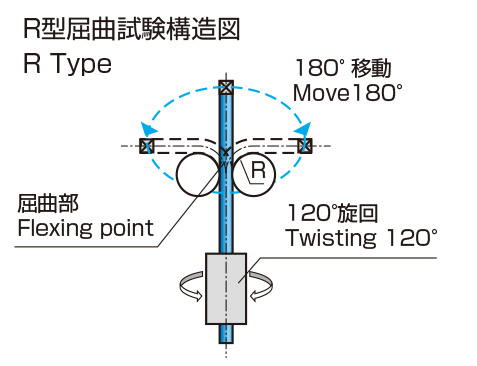

R Type

|

The test method is combined L type and C type test.

Bending at speed of 60times/min. The outer damage and the conductor disconnection are inspected.

R = 6D(D=Cable diameter)

|

|

|

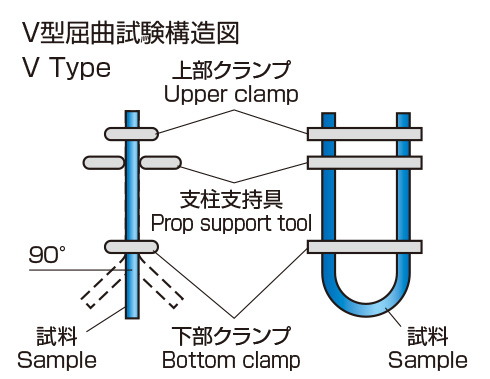

V Type

|

The test method is based on the Quake-resistant test of Denan Law.

Bending each side 45゚. Bending at speed of 200times/min. The outer damage and the conductor disconnection are inspected.

|

|